It has been a busy summer for NEID and its team. Now that the project has officially started, there are many tasks that must be done in a short amount of time. Plans must be made, parts must be ordered, and blogs must be written! Out of all this excitement and bustle, though, there is one important takeaway: NEID construction is underway! Today we will briefly highlight the effort our summer students have put into fabricating NEID’s environment control system.

Background

In order to achieve the sub-meter-per-second Doppler velocity measurement precision required of NEID, there are dozens of sources of instrumental error that must be controlled as tightly as possible. One of those variables is the thermo-mechanical stability of the spectrograph and its optics. As the temperature changes within the instrument, the glass optics or their mounts will change shape or position slightly. Temperature and pressure changes will also affect the index of refraction of any air in the instrument, altering the motion of photons. The impact of these environmental changes on our measurements of the stellar spectra can be much greater than the changes we expect to see from orbiting exoplanets, so they must be mitigated!

Like its predecessor spectrograph the Habitable-zone Planet Finder (HPF), NEID will be outfitted with an environmental control system (ECS for short) to keep the temperature and pressure within the spectrograph as stable as possible. The entire spectrograph will be surrounded by a temperature-controlled aluminum box called a “radiation shield,” which itself is encased in a high-quality vacuum chamber. The high vacuum eliminates heat transport by convection, making it much easier for us to control the temperature of the radiation shield—and thus the instrument itself—to a very precise degree. On the HPF blog, we showed that by using the HPF ECS to simulate conditions for NEID, we could control the instrument’s temperature to better than a thousandth of a degree! This level of precision is required to make the instrument sensitive to Earth-like planets.

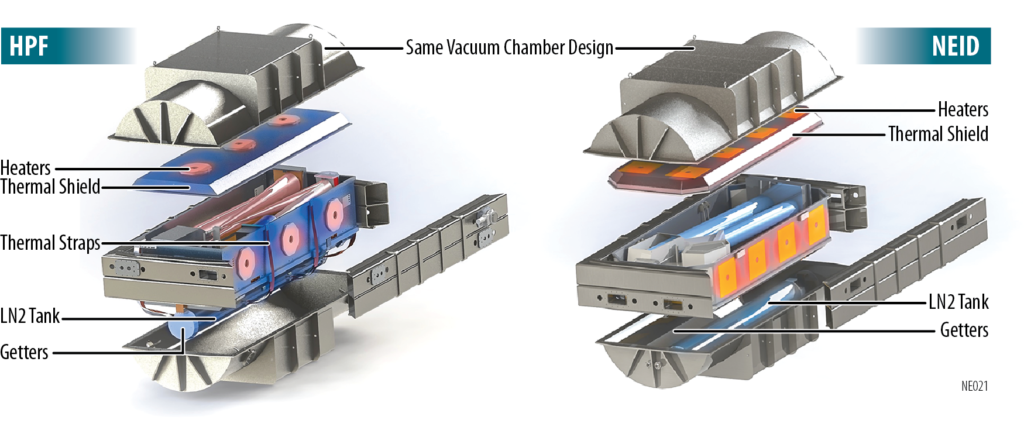

The HPF and NEID instruments, with critical elements of the environmental control system highlighted.

Another requirement for NEID is that it must fit within approximately the same physical dimensions as HPF in order to be housed in the WIYN Telescope’s instrument room. As a result, the NEID vacuum chamber and radiation shield will look very similar to HPF’s. The image above shows the two instruments, highlighting some of the similarities and differences.

The vacuum chamber is the first major component that must be fabricated for the NEID project. The instrument has to have a home, after all! Thus, while the vacuum chamber itself is being built by our collaborators at Pulseray, the team at Penn State has been busy working on everything that goes inside it. Let’s take a quick look.

Let’s build it—again!

Because NEID utilizes nearly all of the technology we developed for HPF, it is much quicker and easier to build a second system. Many of the growing pains of achieving sub-milliKelvin temperature control have already been experienced, and we can simply get things right the first time. With that said, this is still no easy job! As shown in the figure above, NEID has twice as many active heaters as HPF, and the sheer amount of cabling required to operate so many heaters and thermometers is daunting. The optical bench is also larger for NEID, leaving less space to work with during assembly, so the design and application of the multi-layer insulation must also be carefully considered.

Students Demetrius Tuggle, David Conran, and Joe Smolsky assemble a wiring harness for the NEID ECS.

One advantage of building an instrument at a world-class university like Penn State is that there is never a shortage of talented young scientists to help with major projects. We are fortunate to have four undergraduates—David Conran and Adam Dykhouse from Penn State, Joe Smolsky from the University of Nebraska at Omaha, and Demetrius Tuggle from the Ohio State University—helping us to fabricate the NEID ECS over the summer.

With the help of these hardworking students, fabrication of the environment control system’s heaters, thermometers, control electronics, and the half-mile or so of associated cabling is nearly complete! Assembly of the many MLI blankets is now underway as well.

Gudmundur Stefansson supervises the assembly of an MLI blanket.

Moving so fast on the first major component of the NEID instrument is not just critical for completing a subsystem before classes start again in the Fall. It is essential for keeping to NEID’s aggressive project schedule and having the instrument ready to follow up all of the exciting exoplanets that NASA’s Transiting Exoplanet Survey Satellite (TESS), to be launched in 2017, will discover.